KASAGI is a farm and wool specialty company founded in 2020 by Mai and Masato Kasagi. It is located in the Sanbe Mountain area of Japan, which has long been known as a grazing land for cattle.

We have raised sheep at this small, family-run, regenerative farm. Starting with four ewes, the farm now has 24 sheep.

KASAGI believes that high-quality wool products come from the health of the sheep. As a result of considering how to ensure the sheep can live peaceful and healthy lives, the farm naturally adopted sustainable methods.

KASAGI envisions a future where people and sheep share wool to live happily together, protecting each other with this precious resource.

Mai has developed methodologies and know-how of using wool, which is considered unsuitable for mass production due to its characteristics, into high-quality products. Compared to mass production, hand-washed KASAGI’s raw wool uses less water, heat, and detergent.

The origin of KASAGI is a craft technique called Homespun, where wool is spun and woven by hand. KASAGI creates and delivers wool products as if a mother were making the wool used by the sheep in the same household easily accessible to everyone.

Sheep Rearing

We run our farm with a focus on ensuring the freedom and health of our sheep, prioritizing their happiness above all. Each sheep is given a name and raised with affection, as cherished members of our family.

Furthermore, based on the Responsible Wool Standard (RWS), we conserve the soil, water, air, and biodiversity in and around our farm.

Shearing

We, who are well-acquainted with our sheep, perform all the shearing. Shearing is essential for the sheep to live healthily. KASAGI views shearing as an important moment where the ownership of wool transitions from the sheep to us.

Hand Washing Raw Wool

The caretakers of the sheep hand wash the raw wool of each individual sheep. Hand washing significantly reduces damage to both the wool and the environment. Hand washing raw wool is one of the key features of KASAGI’s wool product creation.

Spinning

The origin of KASAGI lies in hand-spun yarn. We create yarn using mule spinning machines that closely mimic hand spinning movements. We partner with a wool-specialized spinning mill in the Bishu region. All of KASAGI’s wool products are made from original yarns created in collaboration with the spinning mill.

Weaving & Knitting

We collaborate with experienced craftsmen from the weaving regions of Bishu and Banshu, weaving fabrics with special looms. All knitted products are manufactured using WholeGarment technology, which reduces yarn loss in the manufacturing process.

to know more about us

our features

Our products are distinguished by the wool we use.

We source our raw materials from our own sheep, which we raise ourselves. We then hand wash the wool and use its unique characteristics to create our products.

All products are manufactured in Japan. We collaborate with skilled Japanese craftsmen to produce high-quality wool products. We design our products to ensure that our valuable wool fibres can be used and enjoyed for an extended period. Our aim is to create items that are durable and long-lasting. When you touch our wool products, you’ll feel as though you’re touching a living sheep.

We work with sheep to create wool products that promote “coexistence”.

Product:Fabrics, Carpets and Socks

New Wool Fabrics

Fabrics are our pride. We have developed fabrics from 100% original wool. After being harvested and hand washed in small quantities, the wool is dried in the sun. Then we pick up the wool by the handful and dust it. At this time, the wool with the best texture for the fabric is selected according to a feeling of touch or its gritter.

On our fabrics, there are still some impurities that have not been removed. This is a design that shows our respect for wool. We have spent over 10 years developing a unique wool washing process to produce wool fabrics that preserve the delicate and intricate fiber structure of wool.

Our wool fabric has a complex charm that wool has in its origin, contains contradictory qualities of wetness and dryness, elasticity and suppleness. Our fabric is a completely new wool fabric.

Hand-tafted Wool Rug

Our wool carpets offer the greatest comfort for walking and sitting. Wool that has not been damaged by heat, friction and chemicals retains its natural elasticity, crimp and strength. The wool yarns developed for our carpets are twinned to increase their strength, and the yarns are woven in a high-density, hand-tufted technique, which is a Japanese craft method.

The shape has beautiful rounded and curved lines that can only be achieved by the best craftsmanship. The design is traced directly from the sheep’s sleeping tracks on the snowflake. Thickness and density have been increased to the highest limits of the hand tufting technique. The thickness and density of our wool rugs are among the highest in the world.

Hand-tufted 100% wool rugs make you feel good; they support you by modeling the resilience of our material. This creates a sense of oneness between the person and the wool, similar to the feeling you get when riding a horse.

It is a wool rug that can be used with love and comfort, as if you were cuddling up to a sheep.

Wool Socks

Our wool socks have taken on a shape that is only possible with wool. The softness, elasticity and moisture control properties of wool have made them extremely warm and comfortable to wear.

We are proud of this work, which took several years to develop the yarn and knitting method. You will be surprised by the warmth and comfort you have never experienced before. When you wear it, you will feel just the right amount of warmth without uncomfortable moisture. You will feel protected by the wool. To increase the strength, we have researched our own yarn spinning and knitting methods.

Wool socks come in two types: round toe socks and five finger socks. Both are knitted using the WHOLEGARMENT technique. There are no seams and no elastic fibers, no tightness or stiffness.

1. Quality

1-1 material quality

Our wool products are made from sheep we raise. And our original washing method brings out the best texture in the wool fiber. And the garments are all made in Japan. These features are important for us to produce high quality wool products.

1-1-1 Careful observation of the wool

The quality of wool varies greatly from individual to individual. Therefore, wool is managed on an individual basis. The character and behavior of the sheep greatly affect the quality of the wool. Seeing the sheep leads to knowing the wool.

As we raise the sheep, we begin to gather information about the wool. Our wool products make the most of the personality of the sheep and their wool, with a deep understanding of them.

1-1-2 Wool and eco-friendly hand washing process

1-1-2 Wool and eco-friendly hand washing process

Over the past 10 years, we have developed a washing process of raw fiber. This method produces the best wool raw materials.

Wool is made up of a protein called keratin. It is easily affected and altered by heat, friction and acid. Wool also has a complex structure within its fibers, making it a delicate and fragile material.

We have discovered the value of this delicate, fragile and complex structure of the natural wool fiber. We preserve the structure of the wool as much as possible. Our way is to wash the wool by hand in small quantities, using only warm water at low temperatures and a small amount of mild detergent to avoid damaging the wool.

This process not only protects the wool, but also the environment. By using less heat, carbon dioxide emissions are reduced. It also reduces the amount of water and detergents used. The water we use is natural water from the mountains, and the waste water is also treated through microbiological decomposition.

The natural comfort of our wool products is delivered through these processes.

1-1-3 Manual wool separation

The quality of wool varies depending on the part of the wool. Because the sheep graze freely, foreign matter such as vegetable particles are mixed in with the wool. These impurities are removed manually. Through this process, we can observe the wool one by one.

At this time, the quality of the wool fibers are checked and divided into the most suitable proposal. The quality of the products is enhanced by this selection process.

1-1-4 The Comfort of our Wool

1-1-4 The Comfort of our Wool

Our wool products have a vibrant, warm and comforting feel as if you were touching a sheep. This is because our gentle washing process brings out the elasticity, shrinkage and moisture management functions of wool.

You can see this comfort when it is made into clothing. The garments are light, warm and steam free. When made into carpets, it has a premium bounce feel.

1-2 Japanese Manufacturing quality

1-2-1 Spinning

Yarn production determines the quality of wool products. Our yarns are spun on mule spinning machines in a highly skilled factory in Japan. This primitive spinning machine takes time and effort to turn wool into yarn.

The mule spinning machine has a motion that slowly draws the yarn. This motion allows the yarn to be produced while preserving the delicate elasticity of the wool fibers. The result is a fluffy, light and durable yarn that is ideal for clothing.

The Mule spinning machine is the perfect machine for our wool material.

1-2-2 WHOLEGARMENT

To make the most efficient use of yarn, socks and knitwear are made using the WHOLEGARMENT technique. This technique is good for both wool and the environment, as it requires fewer manufacturing processes and wastes less yarn. It also allows for three-dimensional knitting.

We create wool socks and knitwear with curves that conform to your body to take advantage of wool’s elasticity. WHOLEGARMENT is the best technology for our wool products and the environment.

1-2-3 Combining Craft and Industry

For more than 10 years, we have been spinning wool and weaving fabrics by hand to find the best way to use our material. With the results of this experience, we introduced industrial technology in 2020.

We design wool products by combining the soft texture that can only be created by hand with the beauty that can only be achieved with delicate Japanese industrial techniques.

Therefore, all wool products are original products and have been developed over time. They are unique products that combine the delicacy of craftsmanship with the strength of industrial technology.

1-3 Design policies

1-3-1 Designing from Sheep

We incorporate sheep characteristics that only we know because we raise sheep into the design of our products, such as wool fabrics with impurities and wool carpets in the shape of sheep tracks left in the snow.

1-3-2 Strength

The strength of wool products is important. Wool is a very precious fiber and our treasure. Therefore, our important mission is to develop designs that increase strength and create wool products that can be used for a long time.

Wool is a delicate fiber, and the higher the quality, the lower the strength. We have developed spinning, weaving and knitting methods to increase the strength of its products.

Fabrics are made strong by spinning and weaving yarns. Strong wool yarns are spun and woven in a simple structure. Less textile processing is used to create fabrics with a wool-like feel. To protect the delicate function and comfortable elasticity of wool, we do not use methods such as heavy ironing or shrinking processes. By avoiding damage to the fibers, the strength of the fabric is increased. It also contributes to the comfort of light and warm garments.

Carpets are made stronger by increasing yarn turnover, tuft density and thickness of the carpet. This carpet can be enjoyed for a long time.

We have developed original yarn for our wool socks. The thread weight and the spinning method have been devised. We have also researched how to knit the socks, using WHOLEGARMENT technology with two patented techniques.

The first is four layers of knit. This creates a thick, cushioned sole that resists friction and provides long-lasting strength. The second is at the ankle, a special knitting technique provides a soft but non-slip cuff. There are no elastic bands. This improves the strength and durability of the wool sock, as there is no rubber to break down. The natural elasticity of the wool and the knitting process give them a soft fit. This makes them extremely comfortable to wear.

1-3-3 Plant Dyeing

We offer wool products dyed with plants. Plant dyeing is attractive for complex and beautiful colors. It is also an ecological and wool friendly dyeing method.

In addition, vegetable dyes are sometimes used to protect and extend the life of wool products. Vegetable dye protects and strengthens the surface of wool fibers by creating a film on the surface. It also has an insect repellent effect. We grow our own indigo plants, collect wild lichens and use KAKI tannin.

2 Living along sheep

2-1 Why are we keeping sheep?

The environment in which the sheep grow is important not only for the production of high quality wool products, but also for a healthy life for the sheep. Wool is the link between the sheep and the outside world.

What makes wool unique is that it has the most complex structure of any fiber. This structure works to maintain comfort in response to changing environments. We put a lot of time and effort into creating wool products that respect the nature of wool.

2-2 How to keep sheep

The goal of sheep farming is to ensure that the sheep can live their entire lives. In achieving this aim, the health, freedom and safety of the sheep are paramount.

2-3 Grazing

The sheep graze freely throughout the year, eating fresh grass. The farm is located in the mountains near a national park at an altitude of 300 meters. This mountain has a long history of grazing.

The farm has an abundance of fresh pasture grass, which is the best for sheep. Each sheep is free to eat as much grass as it wants. They can rest, play and ruminate where and when they want.

2-4 With Veterinary Specialists

We have frequent contact with veterinarians specializing in sheep. By sharing the condition of sheep online, changes in sheep can be detected and treated at an early stage. This contributes greatly to the health of the sheep.

Appropriate doses of anthelmintics are used by injection, orally, or as drops to prevent damage from parasites and ticks. Nutritional management is also important. We weigh the concentrates each time and feed only the amount needed. There is no nutritional or caloric imbalance.

We also work with animal health centers. Under the guidance of veterinarians stationed at local animal health centers, we work to manage the sanitation of the rearing environment and prevent infectious diseases. They also share information about infectious disease outbreaks in other parts of the country and the world. Sometimes they request stool tests for sheep that are not feeling well.

2-5 Affection

All sheep are brought up with names. We call them by name, stroke their bodies, and speak to them affectionately. We also value the family relationships of the sheep and raise them in groups so that family ties are not broken.

We run our farm with the relationship between sheep and people in mind. Sheep and people can spend time in peace.

Regarding mating, births are spaced at least two years apart. This is important for the recovery of the mother and the formation of the parent-child bond. If I were a sheep is how we raise our sheep.

3 Sustainability

3-1 Traceability

We can provide completely clear traceability about our products. We offer our products from wool that we have processed from our sheep, and the manufacturing process is also controlled to be clear.

3-2 Regional Contribution

3-2-1 Cooperation with Welfare facility

We offer part of the wool management process to members of welfare institutions. The process of removing impurities is suitable because wool material is light, and does not require special tools.

3-2-2 Landscape Conservation

In the areas where we operate, the population is moving out and the population is aging. To maintain farmland or community space, we send our sheep to the areas that need mowing. Sheep make a significant contribution to maintaining the local landscape.

3-2-3 Community Creation

Every year during the May holidays we have an open farm day. We demonstrate sheep shearing and display our products.

The event attracts many visitors from outside the city. With the help of community members, guests are treated to omusubi, okonomiyaki, pork bowls, and sheep cookies. Create a place where community members and people from outside can meet and work together.

see more at Sustainability at KFS

4 Commendation

4-1 Japan Textile Contest 2020

Grand Prix (Minister of Economy, Trade and Industry Award)

https://www.fdc138.com/jtc/index.html

#Outline of the contest (excerpt from the website)

The Japan Textile Contest is a project to discover and promote textile designers. The proposal of the contest is to revitalize the textile production area, Bishu. To discover and develop a textile designer who will lead the textile industry in the next generation, the contest aims to strengthen the technical, design, and marketing capabilities of the textile industry community, and expande business opportunities.

#Commentary of Head of Jury: Ms. Kanako Kajihara, Kajihara Design Studio, Inc.

The Grand Prix winner stood out among the many proposals for undyed materials this year, and its beautiful colors were visually surprising and appealing. Then there was the elegant roughness of the remaining crimps and knots.

When I touched it, I found it soft and smooth with an appropriate dryness, and its rusticity soothed me. My intuition told me that this was the direction I wanted to take now, and I could imagine the satisfaction I would feel in my future life. As for the intention of the project, I was very interested in the background and thoughts behind the careful and loving yarn making process, which includes hand-washing domestic wool and minimizing the use of heat and chemicals as much as possible.

The designer is conscious of making things that reduce environmental impact by taking the time and effort. I knew the Creator’s way of life and her joy in respecting nature, and I felt a certain relief in the materials born of her kindness.

The creator’s commitment to craftsmanship and care for the sheep and the environment is a remarkable conviction and execution, and it was an opportunity for us to take a fresh look at the functionality and appeal of wool. I would like to introduce it to as many people as possible at home and abroad as the material of the future.

#Kanako Kajiwara Profile Excerpt from HP

http://www.kajihara-design.com/company/

Born in Sapporo, Hokkaido. Graduated from Tama Art University, Faculty of Design, Department of Dyeing and Weaving. Studied in England after working for Issey Miyake Textile Planning Co. Winner of the Grand Prix at TEXPRINT 2005, a European design competition. Founded KAJIHARA DESIGN STUDIO in 2006 and launched KANA COLLECTION, a textile brand that combines materials produced in Japan and sells each season to high fashion houses in Europe and New York.

Collaborated with a Japanese company to design a winning booth for the Premiere Vision Paris PV Award The Grand Jury Prize 2013. Has been involved in branding and global development as a creative director in various fields including fashion, interior design and architecture, and is also actively involved in project planning and designer training to revitalize Japanese manufacturing areas. Awarded the 42nd Senken Prize in 2020. Inaugurated director of CRAHUG, a digital sales support project for factory brands. Chairman of the jury for the JAPAN TEXTILE CONTEST. WWD Sustainability Director Training Instructor and member of the 4th Study Group on Fashion in the Future of the Ministry of Economy, Trade and Industry.

Established “COQ”, a shop/restaurant/guesthouse complex in the forests of Sapporo, Hokkaido, and is currently promoting color healing and circular lifestyles through ethical lifestyles spent with nature.

4-2 Premiere Vision Paris 2023 Maison d’Exception Exhibit

We exhibited our products in the Maison d’Exception universe at the world’s most prestigious fashion materials trade show in Paris, France. By exhibiting, we create opportunities for our overseas customers to directly touch and feel our wool products.

4-3 Chugoku Regional Women’s Business Plan Contest SOERU

Grand Prix (Chugoku Bureau of Economy, Trade and Industry Director-General’s Award)

Contest Overview (excerpt from the website)

This contest aims to support the growth of female entrepreneurs in the Chugoku region and to discover potential entrepreneurs, as well as to promote the emergence of excellent role models by providing a venue for local female entrepreneurs and supporters to meet.

4-4 Product Testing

4-4-1 fiber diameter

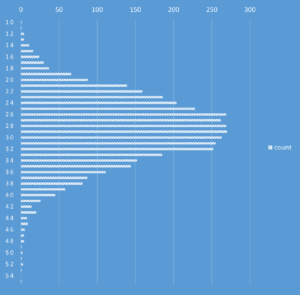

We are also engaged in product testing to objectively determine the characteristics of our products. The graph below shows the results of fiber diameter measurements of our wool raw materials.

The average fiber diameter is 28.67 μm, which is much thicker than the raw material generally used for high-end apparel. Cashmere is often 14 to 16 μm, and high-grade merino wool is around 17 to 19 μm. Fibers this thick are considered unsuitable for apparel, but we manufacture products with a rich texture by carefully processing them according to their characteristics.

4-4-2 KES Texture Test

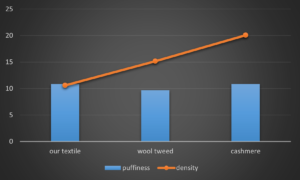

We are also working on the KES texture test (https://english.keskato.co.jp/texture-measurement) to objectively identify texture characteristics. This test qualitatively evaluates various textures (e.g., stiffness, wettability, puffiness, etc.).

Our fabrics are characterized by a great deal of puffiness. This is the sensation of a well-stiffened, plump fabric, as judged by its thickness, which is elastic in compression and accompanied by warmth. It is largely related to the specific gravity of the fabric and its compression characteristics.

Our fabrics have the same plumpness value as cashmere and tweed fabrics, even though they have about half the specific gravity of cashmere. This is thought to reflect the fact that our wool is processed without damage, and thus retains its original lightness and elasticity.

In other words, the natural properties of the wool are maximized, so even though it is lighter than other fabrics, it has a solid presence and warmth.